Mini SMAT packaging machine

Specially designed for small quantities of cardboard box factories, recycling stations, community properties, supermarkets, and logistics parks, as well as for those who pursue instant packaging and limited space utilization, this is a waste paper instant recycling tool that can quickly package and occupy a small area.

A compact and lightweight horizontal packaging machine

What makes people tempted is not only the price and its small and exquisite personality, but also the technological strength and trendy charm of "waste paper recycling at the right time". Continuing the design language of the KBM family, the mini smart packaging machine showcases the same stable style as the KBM series. The overall body is made of military grade manganese steel and forged with advanced technology.

Compact and sturdy body

The core issue of compression and packaging is still quality, so we have designed a 58T driving force for it. When you start the compression packaging, drive the inward squeezing push plate to push the materials to the sliding door and squeeze each other, combined with the solid manganese steel material around the body to generate interaction force, ensuring that the materials are tightly compressed in all directions, including front, back, top, bottom, left, and right, with a maximum of 350-450kg/m ³ The packaging density of. Make packaging more compact and increase value further.

We believe that the best technology is to understand you. After continuous research and optimization, the bundling program for small packaging machines has been redefined. Now, all you need to do is easily hook up the string and tighten it in the hole to complete the bundling. Simple and straightforward, completed in one go.

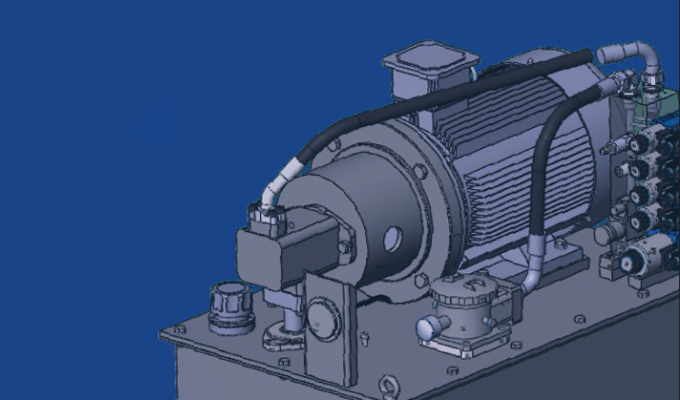

The all-new KHM mini SMART packaging machine is equipped with KBM series intelligent and environmentally friendly hydraulic system, Ф The combination of 150/180mm cylinder diameter and 7.5-18.5kw servo motor drive power, with a maximum pressure of 58T main engine, brings strong propulsion. This hydraulic system is the most powerful power system in the KBM family to date, and it is not one of them. Therefore, whether it is printing cardboard, cardboard boxes, or harder color printing materials, it is effortless.

At the moment you start packaging, the intelligent and environmentally friendly hydraulic system starts working and is driven by a 7.5-18.5kw servo motor Ф The 150/180mm cylinder diameter emits a 58T power to push the material forward and compress it. It performs exceptionally well on cardboard, cardboard boxes, and even harder color printing materials, bringing you a packaging speed of up to 2 tons per hour.

In order to make it more intelligent, we have embedded the core technology of KBM family, PLC intelligent control system. You can easily open and close the cover plate through it, and perform complex operations such as compression packaging, sliding door opening, and pushing out the entire package with just one click. In addition, the system has an automatic reminder function. When packaging is completed, the alarm light will light up, effectively preventing the phenomenon of jamming caused by excessive material placement.

Mini SMAT packaging machine

| model | KHM-H2 | KHM-H4 | KHM-H6 | |||

| Main pressure cylinder | Ф150 | Ф180 | Ф200 | Ф230 | Ф250 | Ф280 |

| Main motor(KW) | 7.5/11 | 15/18.5 | 18.5 | 22 | 30 | 37 |

| Size of feeding port(mm) | W750*L1000 | W750*L1400 | W1050*L1660 | W1050*L1860 | ||

| Bundle size with gate in front(mm) | H600*W800*L900 | H850*W1100*L1300 | H1250*W1100*L1500 | |||

| Bundle size is directly released from the package(mm) | / | H600*W800*L(Free setting) | H850*W1100*L(Free setting) | H1250*W1100*L(Free setting) | ||

| Packaging densityO.C.C(kg/m³) | 350~450 | 350~450 | 350~450 | |||

| Maximum pressure(kg/cm²) | 32Ton(180) | 58Ton(230) | 62Ton(200) | 87Ton(230) | 122Ton(250) | 157Ton(250) |

| Processing capacity(kg/cm³)T/H | about 0.5-1.2 | about 0.8-2.0 | about 2.0-2.5 | about 2.0-3.5 | about 4.5-6.5 | about 5.0-7.5 |

| Number of packages (line) | 3 | 4 | 5 | |||

| Wire diameter(mm) | Ф 5.0 woven tape or wire, 2.8-3.0 relative increase or decrease depending on the packaging material | |||||

| Mechanical dimensions(mm) | H2000*W1268*L5500 | H2530*W5200*L8500 | H2930*W5400*L9000 | |||

| Mechanical weight(T) | 2.8 | 3.2/3.3 | 12 | 12.5 | 16 | 17 |

Our services

Pre sales: (Professional level to earn customer trust)

·Maintain close contact with customers through multiple channels and understand their detailed needs

·Professional engineering personnel come to the site for precise on-site testing and explanation of product performance

·Provide the most comprehensive technical support for terminal and supporting customers, and scientifically and reasonably design the entire set

·Recommend energy-saving and cost-effective products to customers

·Share the latest industry news and promote new products

In sales (tabular progress makes customers worry free)

·The special person in charge follows up on the project and provides a tabular report, making it easier for customers to understand real-time progress

·Complete solutions/installation/foundation circle, establish close communication and contact with customer service providers

·Specialized personnel negotiate installation plans with clients to save installation costs and waste for clients

·Provide customized services based on different types of customers to meet their urgent needs

·The entire factory planning project is delivered in a tabular manner, with independent control over details and installation quality

After sales (humanized service to reassure customers)

·The after-sales service department provides 24-hour free hotline for customer service

·Provide online and offline guidance for customers to regularly maintain and repair equipment

·Regularly provide on-site inspection services for customers

·Archive customer device information and provide free accessory information

·Provide free device upgrade solutions, trade in services, and more