New KBM 3 Series

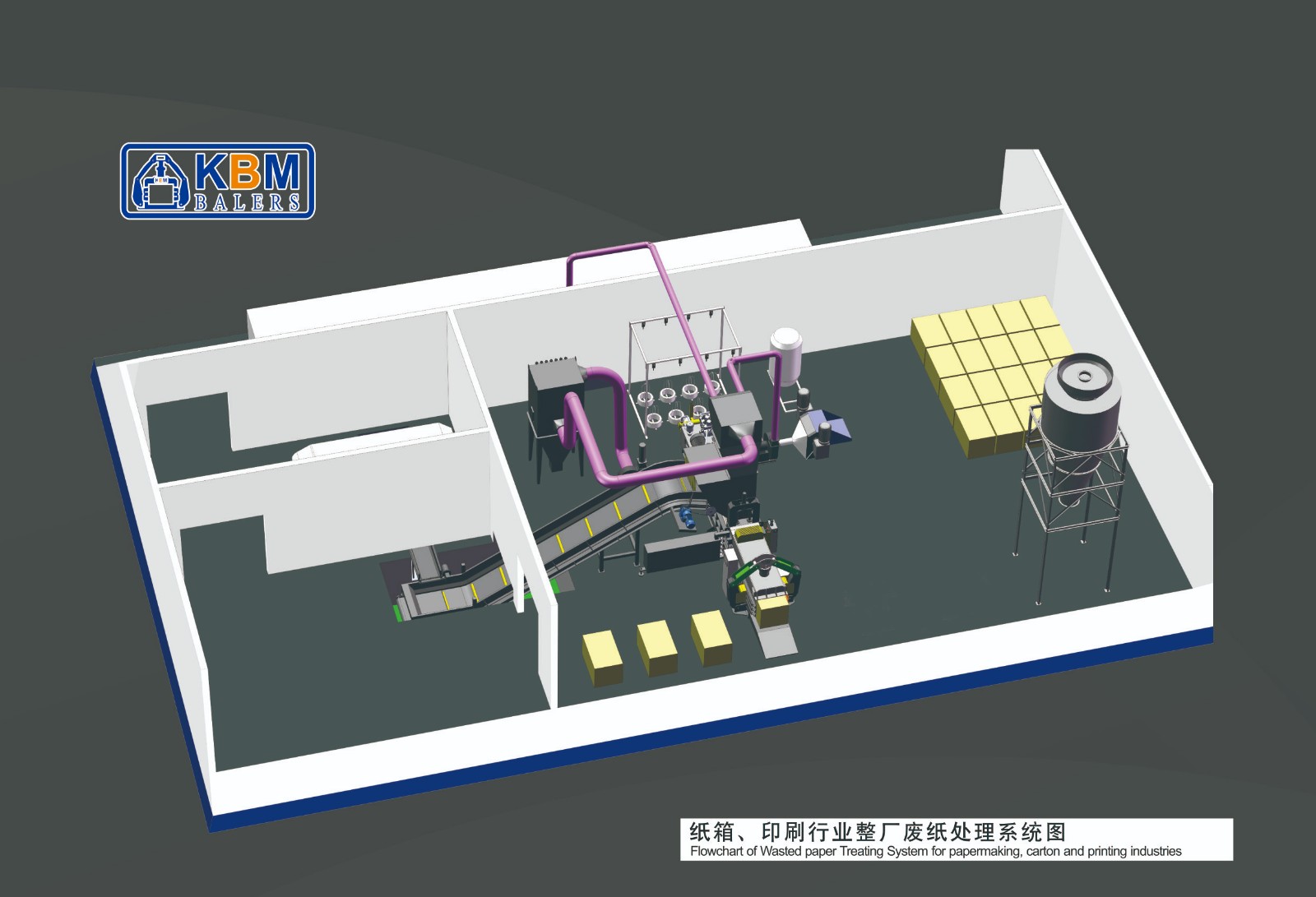

We provide solutions for the cardboard box, printing, papermaking industry, waste cleaning and packaging series, and offer full process consulting services. Any model can be equipped with a conveyor belt or a paper air separator, which can also be equipped with air ducts and fans to transport waste from the production site to the packaging machine

Creating a collection of the essence of technology from past generations

he new KBM3 series, as the first product in this series, combines the technological essence from 2005 to present, equipped with a newly developed KBM series dedicated new generation intelligent and environmentally friendly hydraulic power system and full automatic sensing function, making compression power more powerful while also having energy-saving characteristics. It is known as the "value model of fully automatic compression and packaging machines", and KBM Jianhua has thus established a reputation.

Design, not just design

The 15 ton body made of military grade manganese steel ensures the high-speed operation of the packaging machine while maintaining its durability and strong wear resistance.

The fully automatic wire hooking and tying device has a simple structure, fast speed, precise action, low failure rate, and is easy to maintain.

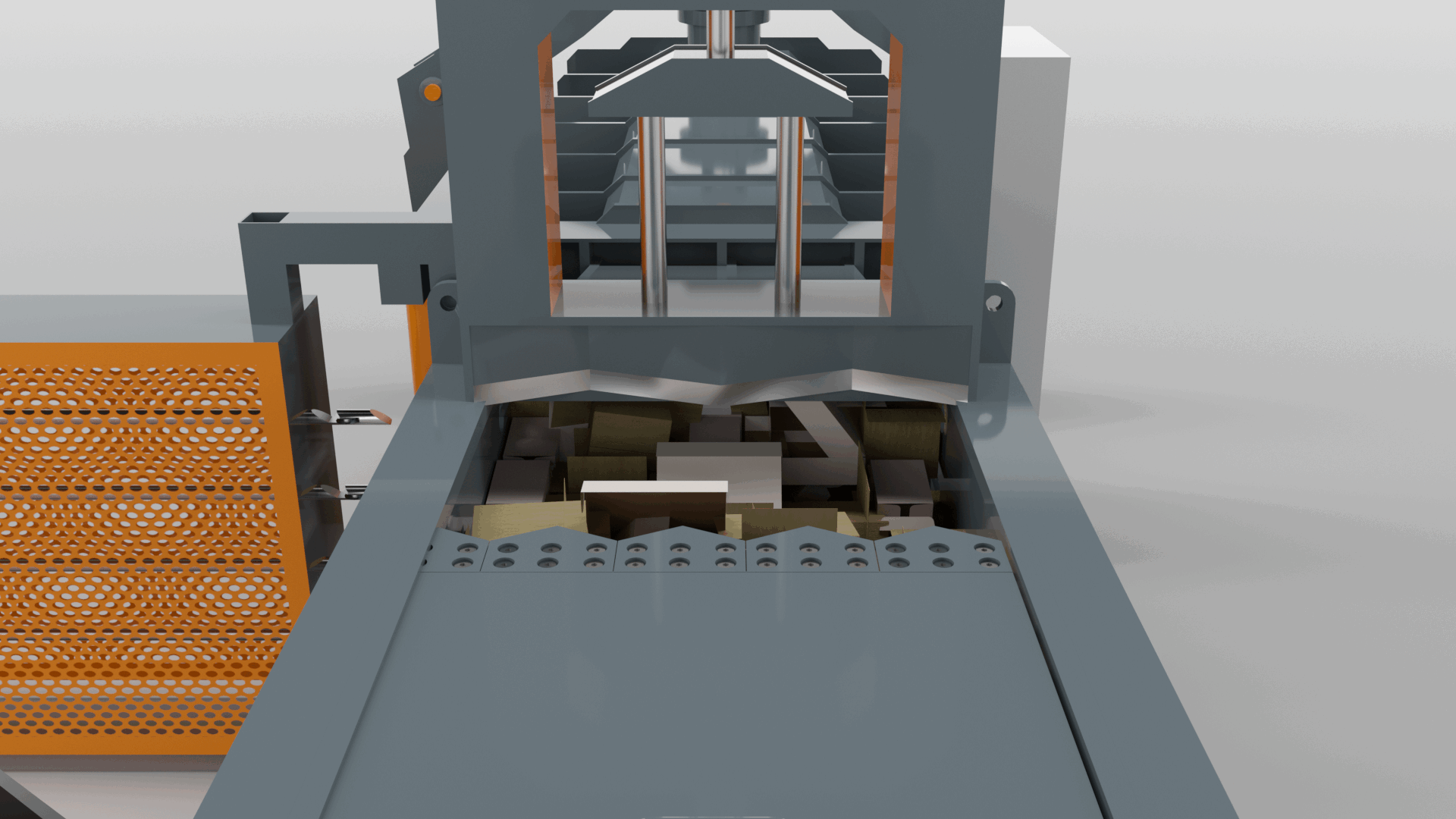

The "W" - shaped dispersed scissor mouth design using imported steel material makes even larger sized cardboard/materials irrelevant here. It can quickly cut the incoming materials one by one, preventing paper jams and creating favorable conditions for faster and tighter packaging.

KBM 3 has a large feeding port that can accommodate cardboard/materials with a maximum size of L1660 * W1050.

Made of manganese steel, both strong and beautiful, cleverly utilizing the principle of lever mechanics, a more compact molding method is used between the double arm clamping and stretching, with a packing density of 350-450kg/m ³。

Speed, derived from strength

Newly developed and upgraded KBM hydraulic system, Φ The combination of a 250mm cylinder diameter, up to 1200L fuel tank capacity, and 37.5KW servo motor drive provides a powerful 122T drive, bringing you a packing speed of 8 tons per hour. Comfortable homework is essential.

Intelligence, surpassing instinct

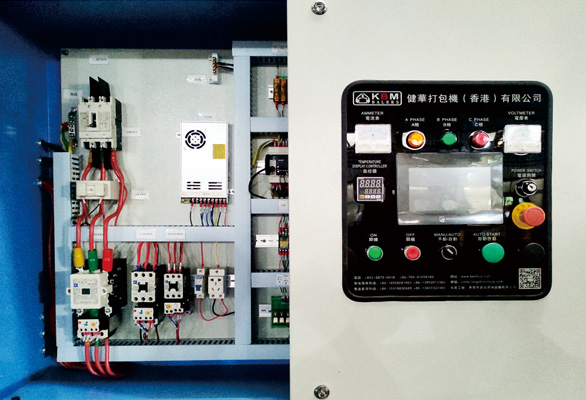

Here, you can complete the settings for various actions of the entire machine on one screen. You just need to set the packaging size and click start, and KBM3 will automatically complete the rest of the actions, making packaging easier and more fun. It can also automatically sense the entire process, and when the material is not full or full, the packaging machine actively maintains a low-speed operating state or immediately automatically accelerates the operation. KBM's unique intelligent control system also comes with an automatic problem detection function and provides simple solutions to help customers solve some simple fault problems on their own, elevating intelligent packaging to a new level.

Energy consumption, lower it a bit

The all-new KBM 3 adopts an organic combination of oil pump, motor, multifunctional integrated block, hydraulic valve and other components, which can form various hydraulic circuits according to the needs of any electrical energy during the operation of the packaging machine, and brake with smaller electrical energy.

The newly upgraded oil circuit system manufactures multi-channel, efficient and energy-saving oil circuits, reducing the back and forth time of the equipment's compression action by 50%.

Leading technology allows fish and bear paws to have both. With a responsive infrared sensing device and PLC intelligent control, the packaging machine can automatically recognize the amount of material in the chamber, making decisions to start packaging or wait for materials. Automatically in a waiting state when the material is not full to save electricity; When the material meets the packaging requirements, it will automatically start. This intelligent design can keep the packaging machine in a power-saving state for 20% -50% of the time, further reducing energy consumption.

Configure your KBM-3

Adopting steel structure skeleton and chain plate transportation, durable and continuously automatic feeding

Using advanced pulse principle, the dust attached to the filtering medium (bag or filter cartridge) is removed by spraying compressed air, ensuring a dust removal rate of over 99.5% on site. The dust removal ability is strong, the dust removal efficiency is high, the emission concentration is low, the air leakage rate is small, the energy consumption is low, the footprint is small, the operation is stable and reliable, environmental protection and energy saving, and the economic benefits are good.

Further saving space, specifically designed for factory customized secondary dust removal systems, and suitable for customer types with limited site conditions and a large number of pipelines

KBM-3 series parameters

|

Name | 3系 3series | KBM-310 | KBM-320 | KBM-325 | KBM-330-A | KBM-330-B | KBM-330-C | KBM-340/350 |

|

Baler | Motor | 7.5/11KW | 15KW | 18.5KW | 22KW+5.5KW | 22KW+5.5KW | 22KW+5.5KW | 30/37.5KW+5.5KW |

|

Baler | Max Pressure | ¢150(MA*200kg/cm²)41ton | ¢180(MA*200kg/cm²)50ton | ¢200(MA*200kg/cm²)62ton | ¢220(MA*250kg/cm²)95ton | ¢220(MA*250kg/cm²)95ton | ¢230(MA*250kg/cm²)103.8ton | ¢250(MA*250kg/cm²)122.6ton |

|

Baler | Bale Size | W600*H600*L(Free setting) | W750*H750*L(Free setting) | W800*H800*L(Free setting) | W914*H750*L(Free setting) | W850*H800*L(Free setting) | W800*H850*L(Free setting) | W1100*H800/850*L(Free setting) |

|

Baler | Feed opening Size | L1000*W500 | L1200*W700 | L1500*W750 | L1660*W864 | L1660*W800/1500 | L1660*W750 | L1660/1860*W1050 |

|

Baler | Operation Mode | (AUTO) | (AUTO) | (AUTO) | (AUTO) | (AUTO) | (AUTO) | (AUTO) |

|

Baler | Oil Tank Volume | 500L | 600L | 700L | 900L | 1000L | 1000L | 1200L |

|

Conveyor | Motor | 4KW | 4KW | 4KW | 5.5KW | 5.5KW | 5.5KW | 5.5KW |

|

Conveyor | Width | 800 | 1000 | 1200 | 1500 | 1500 | 1500 | 1500 |

|

Conveyor | Angel | 33°±3° | 33°±3° | 33°±3° | 33° | 33°±3° | 33°±3° | 33°±3° |

|

Line-cutting machine | Wire of use | 3条(Lines) | 3/4条(Lines) | 3/4条(Lines) | 3/4条(Lines) | 3/4条(Lines) | 4条(Lines) | 4条(Lines) |

|

The diameter of steel wire | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials | 2.8-3.0Corresponding increase or decrease according to different packaging materials |

|

Baling Density | Paperboard/Box | 350〜450(FOR O C C) | 350〜450(FOR O C C) | 350〜450(FOR O C C) | 350〜450(FOR O C C) | 350〜450(FOR O C C) | 350〜450(Printing paper products) | 350〜450(FOR O C C) |

|

Baling Capacity | Paperboard/Box | 约 0.5〜1.0/1.5〜2吨/H (about 0.5〜1.0/1.5-2 tons/ | 约 0.5〜1.0/1.5〜2吨/H (about 0.5〜1.0/1.5-2 tons/ | 约 0.5〜1.0/1.5〜2吨/H (about 0.5〜1.0/1.5-2 tons/ | 约 3〜5吨/H (about 3〜5 tons/H) | 约 3〜5吨/H (about 3〜5 tons/H) | 约 3〜5吨/H (about 3〜5 tons/H) | 约 5〜8吨/H (about 5〜8 tons/H) |

|

Total Weight | 约6+4=10吨 | 约8+4=12吨 | 约9+4=13吨 | 约12+4=16吨 | 约12+4=16吨 | 约13+5=18吨 | 约15+6=21吨 |

outline drawing

Our services

Pre sales: (Professional level to earn customer trust)

·Maintain close contact with customers through multiple channels and understand their detailed needs

·Professional engineering personnel come to the site for precise on-site testing and explanation of product performance

·Provide the most comprehensive technical support for terminal and supporting customers, and scientifically and reasonably design the entire set

·Recommend energy-saving and cost-effective products to customers

·Share the latest industry news and promote new products

In sales (tabular progress makes customers worry free)

·The special person in charge follows up on the project and provides a tabular report, making it easier for customers to understand real-time progress

·Complete solutions/installation/foundation circle, establish close communication and contact with customer service providers

·Specialized personnel negotiate installation plans with clients to save installation costs and waste for clients

·Provide customized services based on different types of customers to meet their urgent needs

·The entire factory planning project is delivered in a tabular manner, with independent control over details and installation quality

After sales (humanized service to reassure customers)

·The after-sales service department provides 24-hour free hotline for customer service

·Provide online and offline guidance for customers to regularly maintain and repair equipment

·Regularly provide on-site inspection services for customers

·Archive customer device information and provide free accessory information

·Provide free device upgrade solutions, trade in services, and more