Coconut, straw, fiber series

Coconut, straw, fiber series(KBM-1173-60、KBM-1173-80、KBM-1111-100、KHM-1111-120)

The vertical bundling method specially designed for the characteristics of coconut palm and straw materials, as well as the unique gantry mouth packaging structure, make the packaging shape particularly flat and solid.

High density packaging blocks have a very high density. Generally, a 40 foot container can only hold 15-18 tons of packaging blocks pressed by a packaging machine, while our container can hold 20-23 tons.

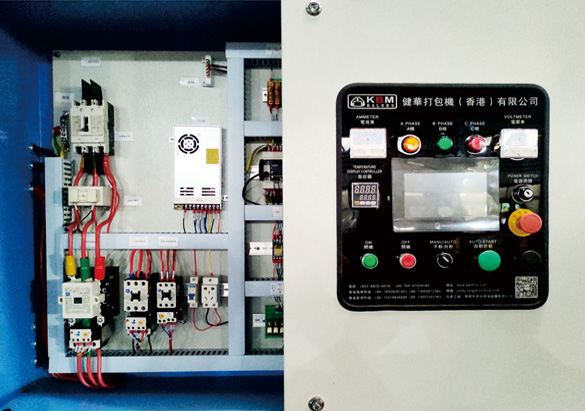

The synchronous action indication diagram, combined with fault indication, timely displays the operation status of the machine, with simple operation and easy maintenance.

Low noise oil pressure circuit system, efficient and low failure rate, power control helps save energy. When the material box is not full, the machine is in a low-speed operation state. When the material box is full, the machine intelligently operates automatically to achieve energy-saving goals. Using original imported hydraulic accessories, with stable performance and durability.

Coconut brown, straw, fiber series parameters

| Model | / | KBM-1173-60 | KBM-1173-80 | KBM-1111-100 | KBM-1111-120 |

| Baler | Motor | 22KW*2 | 30KW*2 | 37.5KW*2 | 45KW*2 |

| Baler | Main Pressure | ¢250(MA*230kg/cm²)112ton | ¢250(MA*230kg/cm²)112ton | ¢280(MA*230kg/cm²)140ton | ¢280(MA*230kg/cm²)140ton |

| Baler | Bale Size | W1000*H730*L(Free setting) | W1000*H730*L(Free setting) | W1000*H1100*L(Free setting) | W1000*H1100*L(Free setting) |

| Baler | Feed opening Size | L1400*W950 | L1400*W950 | L1660*W950 | L1660*W950 |

| Baler | Operation Mode | (AUTO) | (AUTO) | (AUTO) | (AUTO) |

| Baler | Oil Tank Volume | 1000L | 1200L | 1600L | 1800L |

|

Conveyor | Motor | 4KW | 4KW | 5.5KW | 5.5KW |

|

Conveyor | Width | 1000 | 1000 | 1200 | 1200 |

|

Conveyor | Angel | 33° | 33° | 33° | 33° |

|

Line-cutting machine | Wire of use | 5 line | 6 line | 6 line | 6 line |

|

Baling Capacity | 1.5~2T/Hr | 2~2.5T/Hr | 3~4T/Hr | 3.5~5T/Hr | |

| Machien Weight | Total Weight | about 16Ton | about 18Ton | about 23Ton | about 25Ton |

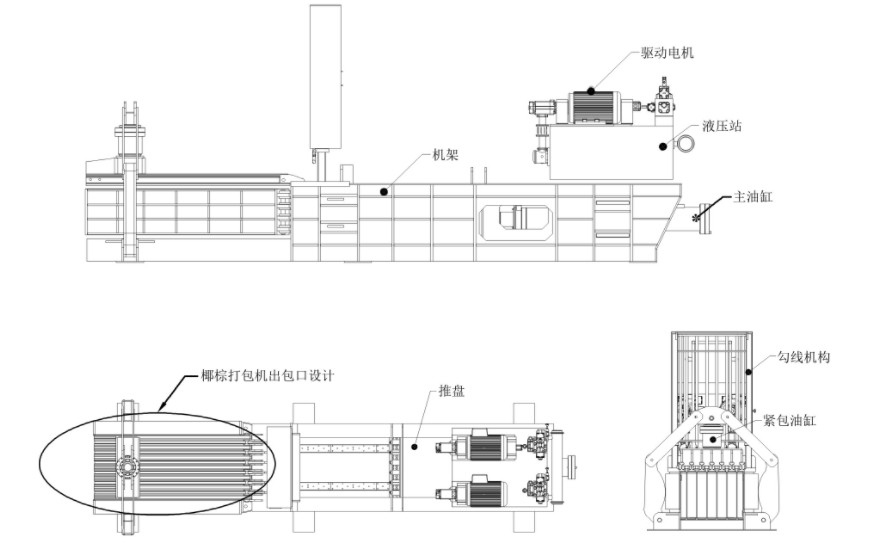

outline drawing

Our services

Pre sales: (Professional level to earn customer trust)

·Maintain close contact with customers through multiple channels and understand their detailed needs

·Professional engineering personnel come to the site for precise on-site testing and explanation of product performance

·Provide the most comprehensive technical support for terminal and supporting customers, and scientifically and reasonably design the entire set

·Recommend energy-saving and cost-effective products to customers

·Share the latest industry news and promote new products

In sales (tabular progress makes customers worry free)

·The special person in charge follows up on the project and provides a tabular report, making it easier for customers to understand real-time progress

·Complete solutions/installation/foundation circle, establish close communication and contact with customer service providers

·Specialized personnel negotiate installation plans with clients to save installation costs and waste for clients

·Provide customized services based on different types of customers to meet their urgent needs

·The entire factory planning project is delivered in a tabular manner, with independent control over details and installation quality

After sales (humanized service to reassure customers)

·The after-sales service department provides 24-hour free hotline for customer service

·Provide online and offline guidance for customers to regularly maintain and repair equipment

·Regularly provide on-site inspection services for customers

·Archive customer device information and provide free accessory information

·Provide free device upgrade solutions, trade in services, and more